In the realm of woodworking, the process of attaching wood to a lathe is a critical operation that demands precision, technique, and a thorough understanding of the equipment involved. This encompasses aspects such as the selection of appropriate mounting systems, the use of accurate centers, and the optimal alignment of the wood blank to achieve rotational symmetry and balance. Mastering this fundamental skill not only enhances craftsmanship but also allows for the creation of intricate designs and forms. To explore the intricacies of this process and elevate your woodworking projects, delve into the following detailed guide on how to attach wood to a lathe.

How To Attach Wood To A Lathe: A Step-By-Step Guide

Understanding Lathe Components

Explanation of lathe parts: headstock, tailstock, bed, and tool rest. Importance of mounting surfaces for effective wood attachment.

A lathe has four main parts that help with woodwork. The headstock holds the motor and drives the spindle. The tailstock supports the other end of the wood and can hold tools.

The bed is the sturdy base that keeps everything steady. Lastly, the tool rest holds the cutting tools close. Properly mounting the wood on these surfaces ensures a safe and smooth operation.

- Headstock: Contains the motor and spindle.

- Tailstock: Provides support and tool holding.

- Bed: The stable foundation of the lathe.

- Tool Rest: Holds cutting tools for easy access.

Choosing the Right Wood for Lathe Work

Types of wood suitable for turning. Factors to consider: grain, density, and moisture content.

Choosing the right wood is like picking your favorite ice cream flavor—everyone has their taste! For turning, softwoods like pine and hardwoods like maple are popular picks. Think about the grain; a nice pattern can make your project pop!

Also, consider the density: denser woods can be tough, but they give a great finish. Lastly, moisture content matters. Too much moisture, and your wood might warp or crack faster than you can say “oops!”

| Type of Wood | Grain | Density (g/cm³) | Moisture Content (%) |

|---|---|---|---|

| Pine | Open grain | 0. 5 – 0. 6 | 15 – 20 |

| Maple | Closed grain | 0. 6 – 0. 8 | 8 – 12 |

| Oak | Coarse grain | 0. 7 – 0. 9 | 10 – 15 |

Essential Tools and Materials for Attachment

List of necessary tools: faceplate, chuck, and screws. Recommended types of adhesive for temporary or permanent attachment.

To successfully attach wood to a lathe, you need some key tools and materials. Here are the essentials:

- Faceplate: This helps to hold the wood securely while turning.

- Chuck: A chuck makes it easy to grip the wood for precise work.

- Screws: Use screws to firmly attach the wood to your tools.

For attachment, you may consider these types of adhesives:

- Wood glue: Great for strong, permanent bonds.

- Double-sided tape: Perfect for temporary attachment.

With these tools and materials, you’ll be ready to start your project!

Preparing the Wood for Lathe Attachment

Steps for cutting and shaping wood blocks before attaching. Safety precautions to take when working with raw wood.

Cutting and shaping wood blocks can be fun, like playing with giant building blocks! Before you attach the wood to the lathe, remember to measure twice and cut once. Start by selecting a block that’s not too big for your lathe—nobody wants a wood monster spinning out of control!

Use a saw to trim the edges and get your desired shape.

Smooth it out with sandpaper; think of it as giving your wood a spa day! But wait! Safety first: wear goggles to protect your eyes and ear protection, too.

That loud noise? It’s a wood party, and you don’t want to be the one without earplugs!

| Steps to Prepare Wood | Safety Precautions |

|---|---|

Choose the right block. | Wear safety goggles. |

Measure and mark your cuts. | Use ear protection. |

| Cut edges and shape. | Work in a well-lit area. |

| Sand for smoothness. | Keep long hair tied back. |

Now you’re ready for the lathe! Let the woodwork adventures begin!

Methods for Attaching Wood to the Lathe

Detailed instructions for using a faceplate. Stepbystep guide for using a scroll chuck.

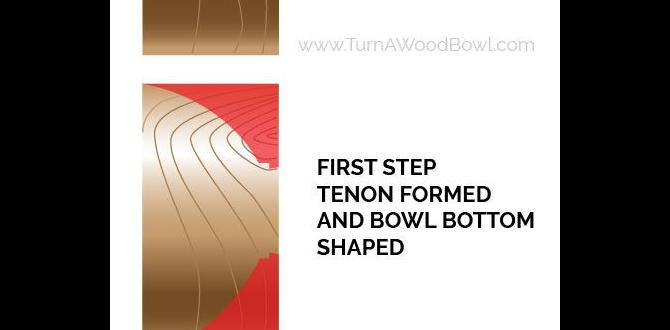

Attaching wood to a lathe can be done in different simple ways. Using a faceplate is one method. Here’s how:

- Secure the faceplate to the lathe spindle.

- Place the wood block on the faceplate.

- Use screws to attach the wood firmly.

Another popular method is the scroll chuck. Follow these steps:

- Attach the scroll chuck to the lathe.

- Open the jaws of the chuck.

- Insert the wood and close the jaws.

Both methods will keep your wood steady for turning.

Securing the Wood: Tips for Better Stability

Techniques for ensuring wood is centered and balanced. Adjustments to prevent vibration during turning.

To keep wood steady on a lathe, start by making sure it’s perfectly centered. A wooden friend that’s off-center can really shake things up—think of it as the wood’s dance party gone wrong!

Use a live center or a faceplate to secure it tightly.

This helps avoid any unwanted wobbles. If your wood starts vibrating like a crazed maraca, it’s time for adjustments. Check that all screws and clamps are secure. Tighten them up and enjoy smoother turning.

| Technique | Description |

|---|---|

| Centering | Ensure wood is even and balanced |

| Secure Locks | Tighten clamps and screws to avoid shaking |

Common Mistakes to Avoid When Attaching Wood

Pitfalls in alignment and mounting methods. Signs of improper attachment and how to correct them.

Attaching wood to a lathe sounds simple, but tiny mistakes can lead to huge problems. First, check your alignment. If the wood doesn’t sit straight, it might wobble like a dancer after too many spins! Look for signs of improper attachment, like uneven cuts or scary vibrations.

Luckily, fixing it is easy: loosen the chuck, realign the wood, and tighten it back securely. This way, your wood can spin smoothly without the drama!

| Common Mistakes | Signs of Improper Attachment | How to Correct |

|---|---|---|

| Poor alignment | Wobbling or uneven cuts | Loosen, realign, and tighten |

| Incorrect mounting method | Vibrations or noise | Check mounts and adjust |

Maintenance After Wood is Attached

Cleaning and checking wood stability during the turning process. Tips for maintaining the lathe after wood attachment.

After attaching wood to a lathe, it’s important to keep everything clean and stable. Regular cleaning prevents dust buildup, which can affect performance. Check the wood’s stability during turning.

Loose pieces can cause accidents.

- Wipe surfaces with a cloth.

- Inspect the wood for cracks or movement.

- Ensure lathe parts are tight and secure.

- Lubricate moving parts as needed.

These tips will help maintain your lathe and ensure safe, smooth turning.

Conclusion

In conclusion, successfully attaching wood to a lathe is crucial for achieving precision and quality in your turning projects. By following the proper techniques—such as ensuring a secure fit with tailstocks, using appropriate chucks, and checking for balance—you can enhance your woodworking experience. With these tips in mind, you’ll be well-equipped to create stunning wooden pieces with confidence.

FAQs

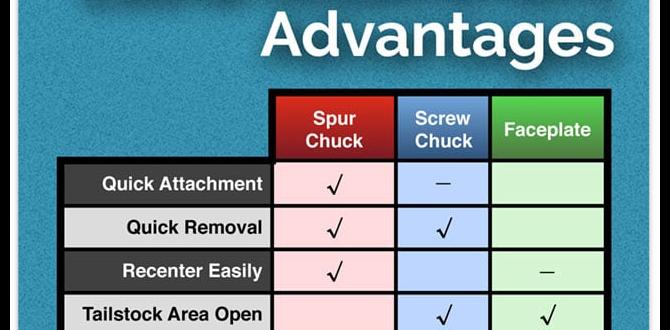

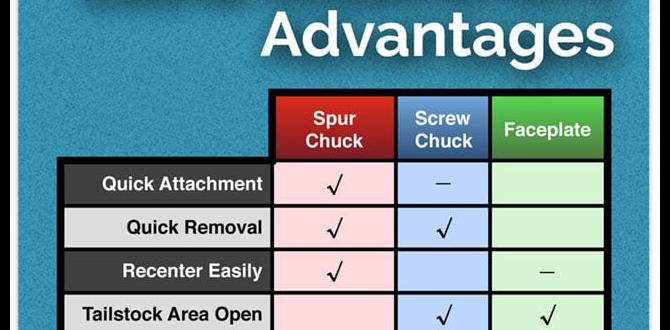

What Are The Different Types Of Wood Lathe Chucks Available For Securing Wood Pieces?There are several types of wood lathe chucks available for securing wood pieces, including scroll chucks, which feature adjustable jaws for a firm grip; collet chucks, known for their precision and ability to hold a variety of sizes; faceplates, used for larger, flat pieces by securing them with screws; and single-axis chucks, which allow for easy centering of the workpiece. Each type offers different advantages depending on the project requirements and the type of wood being used. Additionally, some chucks are designed for specific tasks, such as bowl turning or spindle work. Choosing the right chuck ensures better performance and safety while working on the lathe.

How Do I Properly Mount A Piece Of Wood Onto A Lathe To Ensure Stability And Safety During Operation?To properly mount a piece of wood onto a lathe, first ensure it is securely attached to the headstock by using the appropriate chuck or faceplate, making sure it is centered and tight. Use a tailstock for added support, aligning it with the center of the wood to prevent movement. Double-check all connections for tightness and ensure the wood is free of defects that could cause it to split or crack. Finally, always wear safety gear and remain alert to any vibrations or unusual sounds during operation.

What Are The Safety Precautions I Should Take When Attaching Wood To A Lathe?When attaching wood to a lathe, always ensure that the workpiece is securely fastened to prevent it from loosening during operation. Wear appropriate personal protective equipment, including safety goggles and a dust mask, to protect against flying debris and dust. Check the lathe for any loose parts or defects before use, and keep hands and loose clothing away from the rotating piece. Finally, maintain a safe distance and ensure proper lighting in the workspace to minimize hazards.

Can I Use A Faceplate To Attach Irregularly Shaped Wood Pieces To A Lathe, And If So, How?Yes, you can use a faceplate to attach irregularly shaped wood pieces to a lathe. First, securely fasten the wood to the faceplate using screws, ensuring that they penetrate into solid areas of the wood to provide stability. If the piece is highly irregular, consider adding wooden blocks or shims to create a more even mounting surface. Finally, mount the faceplate to the lathe and check for balance before starting the lathe to avoid vibrations.

How Do I Check For Balanced Wood Pieces Before Turning Them On A Lathe?To check for balanced wood pieces before turning them on a lathe, first inspect the wood for any significant knots, cracks, or irregularities that could impact balance. Use a caliper or measuring tape to measure the diameter at various points and ensure uniformity. Additionally, you can spin the piece on a flat surface to observe any wobble or imbalance. Finally, if possible, weigh the wood to confirm that it is evenly distributed along its length.